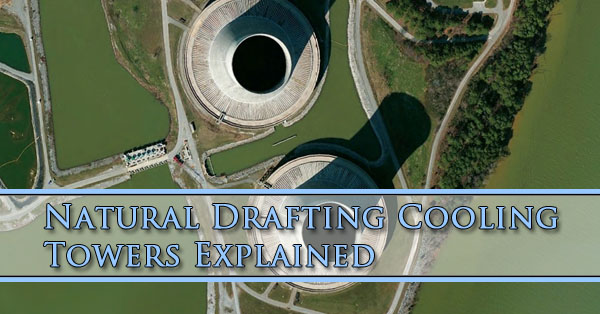

Natural draft cooling towers are the correct option for larger power plants.

The operation of the natural draft cooling works with a stack of effect, causing hot air within the tower to increase (natural draft). The main use for natural draft cooling towers is within the electrical energy industry, however, it can be utilized for various other industrial objects too. These towers let the cooling of higher water volumes while being designed for metal and concrete structures.

The following advantages are provided:

- Environmentally friendly

- Power saving, air flow is not induced with power consumption

- Operation safety

- No fan, no mechanical noise

- Limited plot region

- No re-circulation of rejected plume at higher levels

- High longevity, commonly

- Limited maintenance

- 8 to 16-year payback period

Regions of application

Among industries and power plants that have an unlimited flow of cooling water, the largest cooling tower using natural draft, that we have created to date has a quantity flow rate of 216,000 m3/h.

Key Features

When it comes to cooling, the air stream volume required is produced exclusively by the stack effect. Natural draft cooling towers’ unique economic advantage comes from the very low electric energy requirements. There are minimal operating expenses.

It is an economical solution for higher cooling loads and depreciation in longer periods.

The distance between the air inlet and outlet of the cooling tower avoids re-circulation from warm air which may result in decreased performance.

Almost a full lack of moving parts provides minimal maintenance and higher operating reliability requirements.

Due to the warm air outlet’s height, the surrounding region remains unaffected by the cooling system effects.

Comparison of cold water temperatures and cell cooling towers

Natural draft cooling towers’ cooling air flow volume depends directly on localized conditions such as barometric pressure and air temperature. The air volume stream of cell cooling towers are created using constant and fans. Therefore, varying cooling tower characteristics are created from various local conditions. Under the design, natural draft cooling towers provide cold water temperatures that are more favorable compared to cell cooling towers, and vice versa.

Natural draft cooling tower winter operations

In comparison with mechanical draft cooling towers, cooling air stream volumes of natural draft cooling towers is not controllable directly. With a winter operation, the temperature outside, as well as the thermal load can provide different results. Thus, the control elements that follow can be deployed: zone control, such as disconnecting the individual cooling zones, as well as winter control, such as developing air inlet hot water bypasses.

Winter operation

The construction of the water distribution system is designed to handle about 120% overload. Thus, in the event of an isolated cool zone, extra water is routed by the bypass into the cold water basin, directly. The process utilizes diversion and does not use fittings. There are no problems with the winter start-up.

Disadvantages:

There are a couple of disadvantages to these monolithic cooling towers. Some types of industry and power production necessitate natural draft cooling towers. Companies considering installing cooling towers for industrial or commercial purposes should weigh the load they will have, and choose the cooling tower that best fits their needs and location.

- Increased investment expenses. Due to the size and technology there is a significant difference in the budget necessary to build a natural draft cooling tower.

- A larger size which may lead to challenges with region aesthetics and the requirements of larger regions needing tower installation.

Phoenix Cooling Tower Installation & Repair

If you need to install, service, or have a cooling tower repaired we have the parts, techs, and knowledge to repair any cooling tower in the greater Phoenix area. Don’t wait for your cooling tower to be drawing excessive electricity, get it serviced today. To schedule your maintenance call 1-800-733-1584.